The automotive industry has come a long way since the invention of the first automobile in the late 1800s. It has undergone several revolutions over the years, with each phase bringing more advanced technologies and higher quality materials. Today, the industry is looking for ways to build more efficient and durable vehicles that are environmentally friendly, affordable, and safe.

One of the major developments in the automobile manufacturing industry is the use of Powder Metallurgy Precision Parts. As the name suggests, this involves the use of finely powdered metals to create intricate parts that are used in automobiles. These parts are produced using a process known as Powder Metallurgy (PM).

Powder Metallurgy is a proven manufacturing technology that has been in use for several decades in the automotive industry. The process involves compacting fine metal powders into a die using high temperatures and pressures. This results in a solid metal component with intricate features and a high level of strength and durability.

The use of Powder Metallurgy Precision Parts is becoming more widespread in the automotive industry due to its numerous benefits. First and foremost, these parts are lighter and more compact than their traditional counterparts. This makes them ideal for use in modern vehicles that require high performance and fuel efficiency.

In addition, Powder Metallurgy Precision Parts can be made with high precision and accuracy, allowing for tight tolerances and complex shapes to be produced. This is particularly important for components such as transmission gears and engine bearings, where accurate measurements are critical for performance and safety.

Another advantage of Powder Metallurgy Precision Parts is their superior wear resistance and toughness. The use of powder metallurgy ensures that the components are resistant to wear and tear, which extends the overall longevity of these parts. This makes them ideal for use in high-stress applications that require high-performance metal parts.

Furthermore, Powder Metallurgy Precision Parts offer significant cost savings compared to traditional manufacturing methods. The raw materials used in the PM process are generally less expensive than the materials used in other processes such as stamping and machining. Additionally, the PM process can be automated, reducing the labor costs associated with other manufacturing methods.

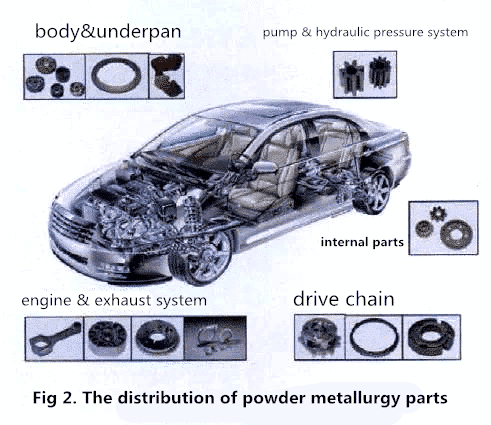

Some of the most common Powder Metallurgy Precision Parts used in the automotive industry include engine bearings, transmission gears, fuel injectors, and shock absorbers. These parts are essential for the smooth operation and performance of modern vehicles.

In conclusion, Powder Metallurgy Precision Parts are the future of the automotive industry. With the numerous benefits of using these parts, it is no wonder why they are becoming more popular among automobile manufacturers. The high precision, durability, and cost-effectiveness of Powder Metallurgy Precision Parts make them an ideal choice for modern vehicles that demand high performance and reliability.